المنتجات الساخنة

Modeling of energy consumption factors for an industrial cement

网页2022年5月9日 Lin, X.Liang, J. Modeling based on the extreme learning machine for raw cement mill grinding process. in Proceedings of the 2015 Chinese Intelligent Automation

Contact

Grinding process optimization IEEE Xplore

网页2017年6月19日 Abstract: As a world-wide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor

Contact

Cement grinding optimisation ScienceDirect

网页2004年11月1日 The cement clinker grinding circuit reduces the feed from 80% passing size between 10 and 20 mm to 100% passing 90 μm.The size reduction takes place in a two-

Contact

Optimization of a fully air-swept dry grinding cement raw

网页2015年4月1日 1. Introduction. Air-swept raw meal ball mills introduced by the cement mill manufacturers F.L.Smidth ® (Smidth, 2002), Polysius ® (Polysius, 2002) and KHD

Contact

(PDF) Pregrinding technology ResearchGate

网页2006年11月1日 In addition, a number of grinding simulations using JKSimMet software conducted to date are presented. The simulation results show that pregrinding increases

Contact

Cement Grinding Cement Plant Optimization

网页Cement grinding operation may be performed in one of the following mill setups. Ball and tube mills. Vertical Roller Mills (VRM). Roller press with Ball mill. Ball Mill. Ball mills with

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 The capacities of grinding mills range from 300 − 1000 TPH for Limestone and for cement grinding it varies from minimum 50 TPH while larger installations are up

Contact

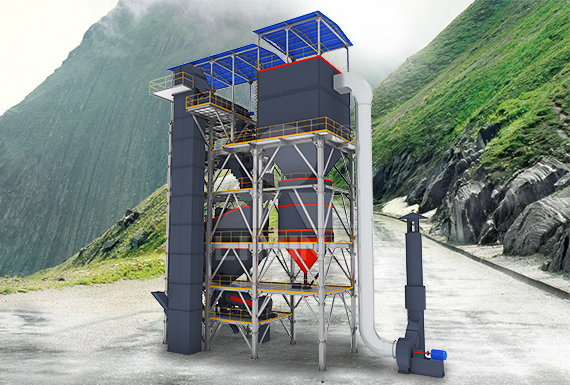

Cement Grinding Unit Cement Grinding Plant Cement Grinding

网页Cement grinding unit cost. Take the annual output of 600,000 tons of large-scale cement grinding station as an example, there are three common options can be recommended:

Contact

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

网页In another word, the cement grinding mill can increase the cement quality and guarantee the qualification rate of cement. In general, cement mill can both apply for dry cement

Contact

Effects of grinding aid dosage on circuit performance and cement

网页2020年12月30日 The use of grinding aids in stirred mills has also been the subject of many investigations and consequently, it was stated that the use of GA in the stirred mills increased the grinding efficiency and reduced the specific energy consumption [15], [16]. Assaad et al. [17] examined the effects of amine and glycol based GAs on cement fineness.

Contact

Modeling of energy consumption factors for an industrial cement

网页2022年5月9日 Lin, X.Liang, J. Modeling based on the extreme learning machine for raw cement mill grinding process. in Proceedings of the 2015 Chinese Intelligent Automation Conference 129–138 (2015).

Contact

Cement Mill Dal Technic Machinery A Company

网页UDCM type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive design. All mill types may operate in either open or closed circuit. UDCM with its

Contact

Cement Grinding Cement Plant Optimization

网页Cement grinding operation may be performed in one of the following mill setups. Ball and tube mills. Vertical Roller Mills (VRM). Roller press with Ball mill. Ball Mill. Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical

Contact

(PDF) IMPROVING PRODUCTIVITY BASED ON THE

网页2019年12月25日 Grinding of clinker for cement production is often performed in a two chamber ball mill. In the first shorter chamber, raw feed is ground using media consisting of large balls.

Contact

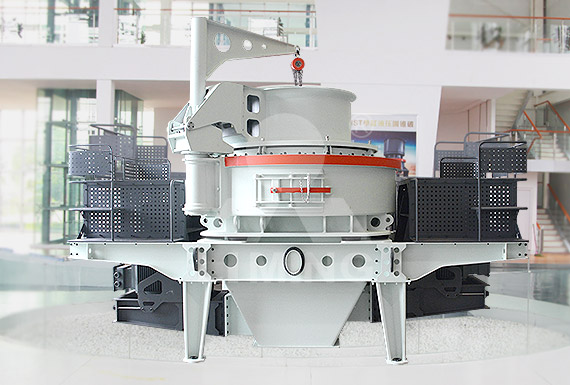

Cement Ball Mill Cement Grinding Machine Cement Mill

网页The cement ball mill is a kind of cement grinding mill.It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power enterprises.It has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust the fineness

Contact

Operational parameters affecting the vertical roller mill

网页2017年4月1日 With the introduction of the high compression machines such as High Pressure Grinding Rolls (HPGR), Vertical Roller Mills (VRM) and Horomills, efficiency of the grinding circuits was improved in terms of energy and downstream effects. Among these devices, vertical roller mills have an important position in cement and mining industry.

Contact

Effects of grinding aid dosage on circuit performance and cement

网页2020年12月30日 The use of grinding aids in stirred mills has also been the subject of many investigations and consequently, it was stated that the use of GA in the stirred mills increased the grinding efficiency and reduced the specific energy consumption [15], [16]. Assaad et al. [17] examined the effects of amine and glycol based GAs on cement fineness.

Contact

Loesche Mills for Cement and Granulated Blast Furnace

网页2017年8月11日 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche. The first use of a Loesche mill, with a grinding track diameter of only 1.1 metres, was used as long ago as 1935. However, the breakthrough in grinding this type of material on the vertical

Contact

Process Training Ball Mill INFINITY FOR CEMENT EQUIPMENT

网页Ball mills for finish grinding cement usually consist of two compartments. An intermediate diaphragm separates both compartments from each other. The 1. compartment is filled with coarser balls and lifting liners and is supposed to pre- grind coarser particles. The 2. compartment is the fine grinding chamber and is equipped with a finer ball

Contact

Energy-Efficient Technologies in Cement Grinding

网页2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

Contact

Optimization of a fully air-swept dry grinding cement raw

网页2015年4月1日 1. Introduction. Air-swept raw meal ball mills introduced by the cement mill manufacturers F.L.Smidth ® (Smidth, 2002), Polysius ® (Polysius, 2002) and KHD Humboldt Wedag® are the most commonly used ones.KHD Humboldt Wedag® manufactured fully air-swept raw meal mills which have two compartments used for drying and grinding processes.

Contact

Cement Grinding Unit Cement Grinding Plant Cement Grinding

网页Cement grinding unit cost. Take the annual output of 600,000 tons of large-scale cement grinding station as an example, there are three common options can be recommended: SCHEME 1: roller press + φ 3.2 ×13m ball mill; SCHEME 2: φ 3.8 ×13m closed mill; SCHEME 3: clinker fine crusher + cement roller press+φ 3.2 ×13m ball mill.

Contact

Cement Mills Optimization--- The Quality Perspective

网页2019年6月13日 Grinding aids are primarily used to carry out three main benefits 1) To reduce Pack Set I.e. Difficulty of starting of cement to flow in dry state 2) To improve cement "Flowability" i.e. the ease

Contact

Cement Mill for Sale Buy Cement Ball MillVertical Roller Mill

网页Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders. Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce.. As a professional cement equipment manufacturer, AGICO has rich

Contact

Cement grinding optimisation ScienceDirect

网页2004年11月1日 Cement grinding simulation. To optimise cement grinding, standard Bond grinding calculations can be used as well as modelling and simulation techniques based on population balance model (PBM). Mill power draw prediction can be carried out using Morrell’s power model for tumbling mills. The case study. Potential benefits of using the

Contact

polysius® booster mill thyssenkrupp Polysius

网页Bead mill working principle for dry cement grinding One crucial characteristic of this mill is the high energy density, 10-20 times higher than of a ball mill, and the resulting very compact design. The bead-stirring elements on the shaft inside the fixed shell reach a tip speed of 5 times the critical speed.

Contact

Cement Mill Dal Technic Machinery A Company of Dal

网页UDCM type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive design. All mill types may operate in either open or closed circuit. UDCM with its special design enables alternative drive systems by. double pinion direct gearbox with girthgear.

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 The capacities of grinding mills range from 300 − 1000 TPH for Limestone and for cement grinding it varies from minimum 50 TPH while larger installations are up to 450 TPH [8]. Many technologies are in use today for grinding processes in the manufacturing of cement, which have been developed over the years.

Contact

Update on Bangladesh, November 2022 Global Cement

网页2022年11月16日 Written by David Perilli, Global Cement 16 November 2022. Print. The Infrastructure Development Company in Bangladesh announced this week that it had agreed to loan Crown Cement US$25m to help it add a new mill to its cement grinding plant at Munshiganj, south of Dhaka. If completed it will be the plant’s sixth mill.

Contact