المنتجات الساخنة

Life cycle assessment of a novel blast furnace slag

网页2022年7月15日 The life cycle energy consumption relating to the slag utilization system was calculated to be about 14 GJ per ton of blast furnace slag input. Detailed contributions to total energy consumption from the perspective of unit processes and energy types

Contact

Synergistic effects of steel slag and wet grinding on ambient

网页2022年9月26日 About 0.29 tons of ground granulated blast furnace slag (GGBFS) were generated for per ton of pig iron, and approximately 1 ton of steel slag (SS) was

Contact

A Review of Granulation Process for Blast Furnace Slag

网页2021年12月4日 energy-saving potential in China. The Blast Furnace (BF) energy consumption account for the largest percentage, and responsibly, it should bear more

Contact

Synergistic effects of steel slag and wet grinding on ambient

网页2022年9月26日 The reactivity of solid waste in cement-based materials can be elevated significantly at a low level energy consumption [36], [37], Self-hydration characteristics

Contact

Specific energy consumption of grinding and powder

网页2011年9月1日 When slag powder is ground to very fine, the specific energy consumption of grinding for W-BOF and A-BOF slags are estimated to be 3.19 and 2.17 times of that for

Contact

Granulated blast furnace slag grinding ResearchGate

网页2000年9月1日 Power consumption: 10 kWh/t dry slag (WBCSD, 2002;Ruhmer, 1992) Fuel consumption: 300 MJ/t dry slag (calculation based on ten per cent moisture and 20 per

Contact

Energy Use of Fine Grinding in Mineral Processing SpringerLink

网页2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done

Contact

“Effect of Foamy slag in Electric arc furnace on Energy efficiency

网页2018年6月13日 Seyed Ahmad Hashemi. Copper loss in the slag of Khatoonabad flash smelting furnace is estimated to be about 1–3 %. At present, the electric slag cleaning

Contact

Specific Energy Consumption of Grinding and Powder

网页2023年2月24日 Specific Energy Consumption of Grinding and Powder Characteristics of Blast Furnace Slag and Basic Oxygen Furnace Slag: GAN Lei,WANG Hai-feng,ZHANG

Contact

Furnace Slag an overview ScienceDirect Topics

网页EAF slag is a by-product of steelmaking industry which, after cooling from temperatures up to 1300 °C to ambient conditions, becomes a dark-gray stony material with a rough

Contact

Oxygen Furnace Slag on Its Grindability mdpi-res

网页2021年9月1日 What’s more, the surface energy of the fine BOF slag particles increases obviously, as the SSA increases to a certain extent, and the particles show a trend of agglomeration [6], resulting in BOF slag being difficult to be ground. So that the grinding efficiency of BOF slag is low and the energy consumption is great [9,10].

Contact

Effect of different grinding aids on property of granulated

网页2014年10月14日 The objective of this study was to assess the feasibility of utilization of grinding aids (GA) in the granulated blast furnace slag (GBFS) powder production. The GBFS powders were prepared with different GA, and their grindabilities, fluidities, reactivities and hydration characteristics were investigated. The experimental results indicate that

Contact

Granulated blast furnace slag grinding ResearchGate

网页2000年9月1日 Power consumption: 10 kWh/t dry slag (WBCSD, 2002;Ruhmer, 1992) Fuel consumption: 300 MJ/t dry slag (calculation based on ten per cent moisture and 20 per cent heat loss from dryer -similar fuel

Contact

“Effect of Foamy slag in Electric arc furnace on Energy efficiency

网页2018年6月13日 Seyed Ahmad Hashemi. Copper loss in the slag of Khatoonabad flash smelting furnace is estimated to be about 1–3 %. At present, the electric slag cleaning furnace is used for the recovery of

Contact

Use of Slags in the Production of Portland Cement Clinker

网页2019年8月28日 Abstract. The use of technogenic raw materials as input products in the production of portland cement provides for considerable reduction of energy consumption during clinker burning. The study reveals the mineral formation features caused by the change of the liquid phase composition and crystallization of silicate phases.

Contact

IRON AND STEEL SLAG USGS Publications Warehouse

网页2022年1月31日 Slag was processed by 28 companies servicing active iron and steel facilities or reprocessing old slag piles at about 124 processing plants (including some iron and steel plants with more than one slag-processing facility) in 33 States, including facilities that import and grind unground slag to sell as ground granulated blast furnace slag

Contact

The Life Cycle Energy Consumption and Emissions of

网页2021年4月20日 Keywords: Basic Oxygen Furnace Slag (BOF); energy consumption; global warming potential (GWP); life cycle assessment; rainy interference condition; production efficiency 1. Introduction Road construction has an adverse effect on climate change. It accounts for around 28% of global energy consumption and approximately 22% of global

Contact

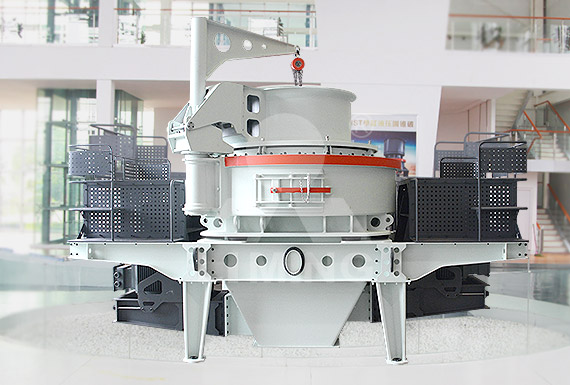

GGBS Production Line Slag Mill for Slag Powder Grinding

网页The open circuit grinding process is the earliest slag powder grinding technology. It has the advantages of simple process, low technical requirements for operators, and low investment cost. The unit power consumption of this system is about 100kWh/t per grinding slag with a specific surface area of 450m 2 /kg. Disadvantages include low

Contact

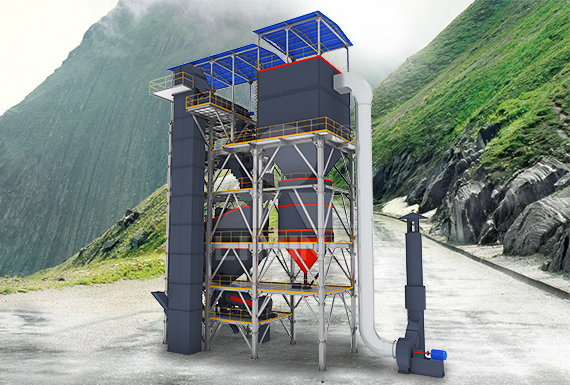

ground granulated blast furnace slag Global Cement

网页2023年5月12日 L'Usine Nouvelle News has reported that the new plant took 24 months to build and cost Euro22m. The main part of the plant consists of a 70m tower, where activated clay, ground granulated blast furnace slag (GGBFS) and gypsum are mixed to produce the cement. It is installed with solar panels capable of supplying 50% of its energy consumption.

Contact

Study of intergrinding and separate grinding of blast furnace slag

网页2000年3月1日 The slag was activated mechanically by grinding the slag to 250, 360 and 420m2/kg Blaine surface area, thermally by curing mortar specimens at 20°, 40° and 60°C, and chemically by mixing the

Contact

Energy efficiency in clinker production Indian Cement Review

网页2017年7月31日 Energy consumption, during grinding operation, whether raw material or finished products is of paramount importance in present circumstances. (OPC), Portland Slag Cement (PPC), wet plants, white plants, grinding plants and clinkerisation plants. The total reported energy consumption of these designated consumers is about 15.01 mtoe.

Contact

Mechanical performance, hydration characteristics and microstructures

网页2022年2月21日 Thereby, the reactivity of solid waste particles was improved effectively at a low energy consumption level. Wet grinding was verified to be an efficient method to elevate the pozzolanic activity for fly ash [43], [46], blast furnace slag [47], [48], [49] and steel slag [50]. So, there is great potentiality for BFFS to be used as SCM in high

Contact

Specific energy consumption of grinding and powder

网页2011年9月1日 When slag powder is ground to very fine, the specific energy consumption of grinding for W-BOF and A-BOF slags are estimated to be 3.19 and 2.17 times of that for W-BF slag respectively.

Contact

Slag recycling recovery

网页The number of granulation plants for blast furnace slag has grown strongly. Since around 2000, the most important Chinese steel producers have been investing in granulation and grinding plants for blast furnace slag. It is currently estimated that 95 % of the blast furnace slag is granulated and used entirely in the cement and concrete industry.

Contact

(PDF) The Life Cycle Energy Consumption and Emissions of

网页2021年4月19日 The Life Cycle Energy Consumption and Emissions of Asphalt Pavement Incorporating Basic Oxygen Furnace Slag by Comparative Study April 2021 Sustainability 13(8):4540

Contact

Synergistic effects of steel slag and wet grinding on ambient

网页2022年9月26日 The reactivity of solid waste in cement-based materials can be elevated significantly at a low level energy consumption [36], [37], Self-hydration characteristics of ground granulated blast-furnace slag (GGBFS) by wet-grinding treatment. Constr. Build. Mater., 167 (2018), pp. 96-105, 10.1016/j.conbuildmat.2018.01.178. View PDF View

Contact

Research Progress on Controlled Low-Strength Materials:

网页For example, the energy required to grind granular blast-furnace slag is approximately 10% of the total energy required to produce Portland cement . Therefore, utilizing metallurgical waste as an SCM is an ideal strategy for lowering the usage and cost of fuel for Portland cement production.

Contact

Synergistic Effects of Steel Slag and Wet Grinding on

网页2022年2月10日 In this study, wet grinding was performed to promote the reaction activity of ground granulated blast furnace slag (GGBFS). In order to further accelerate hydration reaction and shorten setting time, steel slag (SS) was used as partial-substitution precursor. Wet-grinded SS-GGBFS (WSS-GS) binary binders activated by sodium sulfate were

Contact

BLAST FURNACE SLAG BENEFICIATION BY USING INNOVATIVE ENERGY

网页1999年10月21日 Last recorded data (June 95) for total plant (slag reclaiming shop, grinding shop, fuel storage and preparation, groung slag storage, mixing and bulk delivery shop, ancillaries and control room) are : power consumption : 43,52 kWh/t thermal consumption : 476,5 Mj/t Difference in power consumption between the two figures 3,52

Contact

CHAENG Great Wall Machinery-GGBS&Cement Plant,cement grind

网页2017年6月1日 Reduce energy consumption by 30% and increase the amount of processing by 15-20%. 4. The product rate is high, the operation is more stable so the recycling of blast furnace gas in slag grinding plant minimizes the pollution to the surrounding environment, also dispense the high environmental taxes. The recycle of

Contact