المنتجات الساخنة

Review on advances in mineral processing technologies

网页2022年4月1日 The first comminution stage in a mineral processing plant is crushing, which reduces the size of particles from up to 1 m down to 0.5 cm (depending on the type of

Contact

Crushing in Mineral Processing 911 Metallurgist

网页2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy)

Contact

Minerals Special Issue : Advances in Ore Processing MDPI

网页2022年7月31日 Special Issue Information. Dear Colleagues, Advances in the mineral processing steps are constant. Crushing develops more efficient particle breaking,

Contact

Understanding Mineral Liberation during Crushing

网页2020年2月13日 Coarse comminution test-work and modeling are powerful tools in the design and optimization of mineral processing plants and

Contact

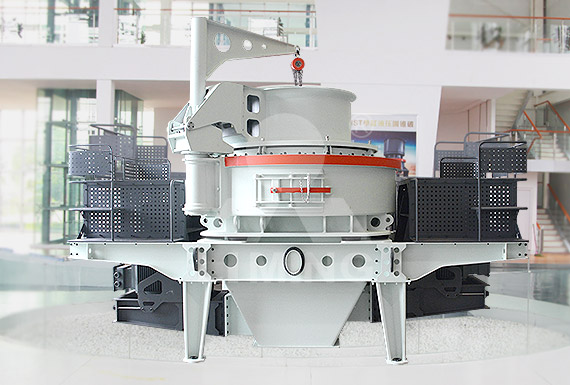

(PDF) Mineral Processing: Crusher and Crushing

网页2020年11月8日 Abstract. Mineral Processing: Crusher and Crushing; Types of Crusher; Types of Crushing; Local Quality and High quality ; International and Country/Hand

Contact

(PDF) SIZE REDUCTION BY CRUSHING METHODS

网页2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by

Contact

Mineral Processing Crushing System Based on Fuzzy Genetic

网页2022年5月23日 In this , the crushing system of mineral processing is taken as the specific research object. According to its characteristics of nonlinear large delay and

Contact

Crushing Mineral Processing 911 Metallurgist

网页2016年1月16日 Crushing Mineral Processing. In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate

Contact

AT CRUSHING TECHNOLOGY Mineral Processing

网页The CRUSHING TECHNOLOGY provides a comprehensive tabular overview of all stationary and mobile crushing plants, which are used in a wide range of applications in

Contact

Understanding Mineral Liberation during Crushing

网页2020年2月13日 Coarse comminution test-work and modeling are powerful tools in the design and optimization of mineral processing plants and provide information on energy consumption. Additional information on mineral

Contact

Primary Crushing SpringerLink

网页This (Truscott) is “the whole operation of reducing the crude ore to the fineness necessary for mechanical separation, or for metallurgical treatment” 1 It is usual to make an arbitrary division of comminution into convenient stages. Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average

Contact

(PDF) SIZE REDUCTION BY GRINDING METHODS

网页2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by

Contact

(PDF) Comminution in mineral processing ResearchGate

网页2018年11月19日 As discussed earlier about crushing process, equipment used for crushing are known as crushers. Crushing is the primary stage of mineral beneficiation. Crushing equipment are divided into two

Contact

Crushing in Mineral Processing Eastman Rock Crusher

网页2020年4月20日 Crushing in Mineral Processing. 2020-04-20 2020-04-20 / crusher plant. The modern industrial use of aggregates began in the early 19th century, and the aggregate can be defined as particles of rock that, when combined in either a bound or an unbound condition, form a part of an engineering or building structure.

Contact

Mineral Processing DECHEMA

网页2012年11月8日 “Mineral processing is the first step in the solid mineral extractive process. The goal is to produce granular mate-rial which meets a specific set of requirements in terms of material composition and physical characteristics (espe-cially granulation). The minerals are then used either as ? Crushing ? Pre-sorting ?

Contact

Mineral Processing an overview ScienceDirect Topics

网页Mineral Processing. Mineral processing, also known as ore dressing, mineral beneficiation, or mineral engineering, is defined as the science and art of separating valuable metallic and nonmetallic minerals from unusable gangues. In such plants, the crushing and grinding equipment shown in Fig. 11 is replaced by a single stage of (primary

Contact

Introduction to Mineral Processing or Beneficiation Sepro

网页2018年1月12日 Within an ore body, valuable minerals are surrounded by gangue and it is the primary function of mineral processing, to liberate and concentrate those valuable minerals. 1.3 Run-Of-Mine Material and Minerals. 3.2.1 Crushing Equipment. Primary Crushers Jaw and Gyratory.

Contact

(PDF) Overview of Mineral Processing Methods ResearchGate

网页2015年8月3日 Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to produce a concentrate containing most of the ore minerals and a

Contact

Crusher an overview ScienceDirect Topics

网页Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers.

Contact

Crushing Energy Efficiency North American Mining Magazine

网页2021年6月10日 According to one estimate, the mining industry consumes 12EJ per year of energy or 3.5% of total final global energy consumption.1 The energy intensity of mining is also predicted to increase over time as deposits that are lower quality, deeper and more difficult to extract are mined.

Contact

Pre-concentration at crushing sizes for low-grade ores processing

网页2020年3月1日 Mineral processing of low-grade ores requires high processing flow rates. Pre-concentration is a clever technological solution for this challenge because the rejection of barren rock, in the early stages of the processing flowsheet, leads to increasing the head grade of the concentration plant and reducing the corresponding input flow rate.. As pre

Contact

Breakage process of mineral processing comminution

网页2020年9月1日 1. Introduction. Nowadays, with the increasing depletion of high grade and coarse-grained ores, the trend is towards the extraction of low-grade ores [1].This can have two consequences for the minerals industry; first to process larger tonnages of mineral raw material and second to grind the raw materials to finer sizes [2], which in turn leads to

Contact

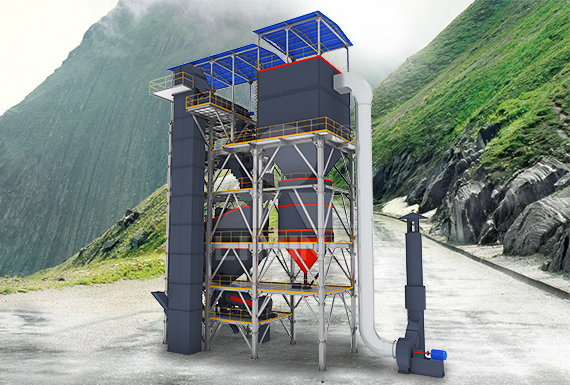

11.19.2 Crushed Stone Processing and Pulverized

网页2015年9月10日 for these products, pulverized mineral processing plants have production rates that are less than 5% of the production capacities of conventional crushed stone plants. Two alternative processing systems for pulverized minerals are summarized in Figure 11-19.2-2. In dry processing systems, the mineral aggregate material from conventional

Contact

Digitalization Solutions in the Mineral Processing Industry:

网页2022年2月7日 The technologies used in mineral process engineering are evolving. The digital mineral processing solutions are based on advances in our ability to instrumentally measure phenomena at several stages of the beneficiation circuit, manage the data in real-time, and to analyze these data using machine learning to develop the next generation of

Contact

Introduction to Mineral Processing Sepro Labs

网页2021年11月22日 Introduction to Mineral Processing 2 1.0 Introduction 1.1 Mineral Processing and Extractive Metallurgy Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use.

Contact

Mineral processing plant crushing and griding automation

网页2021年7月26日 Vibration monitoring of process equipments: -crusher,mill,screen,feeder,conveyer,pump. Vibration Monitoring System composition: Gearbox/Reducer from the equipment → Vibration Sensor → Data acquisition equipment → Software. Functional specification: Vibration acceleration data acquisition and storage.

Contact

OVERVIEW OF MINERAL PROCESSING METHODS

网页2 天之前 7 2.5 Grinding is the stage of size reduction (wet or dry) where the liberation size for individual minerals can be reached. Size reduction by crushing has a size limitation for the final products.

Contact

8 Factors That Affect Production Efficiency of Crushers

网页2021年9月15日 Two jaw crusher factory pictures. The crusher is a crushing machine used in the processing of metal ores and non-metallic ores that can crush the mined raw ore into small particles by means of extrusion and bending. In the actual production process, the production efficiency of the crusher is often affected by various reasons, which directly

Contact

Size Reduction and Energy Requirement ScienceDirect

网页2016年1月1日 The first step in the recovery process of minerals from the host rocks, therefore, is to reduce the size of rock by crushing and grinding. Mineral crushing and grinding circuits. Elsevier Scientific, Amsterdam-Oxford-New York (1977) Google Scholar [12] L.G. Austin. Powder Technol, 7 (1973), p. 315. View PDF View article View in

Contact